Dry lubricants – the alternative for special application cases

Dry lubricants can be classified into powdery solid lubricants, ceraceous sliding films and solidcontent bonded coatings.

Structure of bonded coatings

Bonded coatings are solid lubricants (usually MoS2, graphite or PTFE) that are embedded in a binder. A solvent that evaporates during the curing or drying time is added for the distribution of the bonded coating.

Coating with a bonded coating is carried out after thorough preparation of the surface through immersion, spraying or painting. The dry bonded coating layer is between 10 and 20 μm thick. It withstands high pressure loads and extreme temperatures, does not take up soiling and is characterised by very high chemical stability and an excellent long-lasting lubrication.

Bonded coatings are used in many technical fields, e.g. for nuts, screws, bolts, washers, springs, sealing rings, gearwheels, slideways and threaded spindles.

In comparison to classical lubricants bonded coatings are characterised by

- Dry lubrication without oil and grease

- Clean lubrication without dirt adhesion

- Very low friction values can be achieved

- High temperature resistance

- No evaporation losses

- Use in vacuum possible

- Chemical-physical stability

- Effectiveness also at low sliding speeds

- Long-term and lifetime lubrication

- High cost efficiency

Classification of solid lubricants

Solid lubricants are used as fine powder and can be divided by their structure, as well as into chemically and physically active substances.

The most common ones are listed here.

|

|

MoS2 | Graphite | Zincpyrophosphate | Zincpyrophosphate | Calcium hydroxide | Aluminium | Zinc sulphide | Zinc oxide | Calcium fluoride | PTFE | PE |

| Structure-effective with layer lattice structure |

■ | ■ | |||||||||

|

Chemically effective |

■ | ||||||||||

| Chemically effective without layer lattice structure |

■ | ■ | ■ | ||||||||

| Physically effective with layer lattice structure |

■ | ■ | ■ | ■ | |||||||

| Physically effective without layer lattice structure |

■ | ■ |

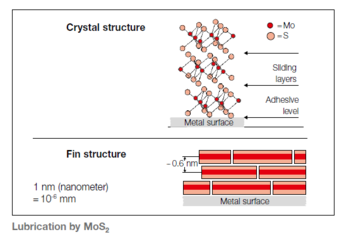

Molybdenum disulphide MoS2

Molybdenum disulphide MoS2

The best lubrication properties at metal pairs are achieved with MoS2 (molybdenum disulphide). The layer lattice structure and the chemically effective properties on the metal surface produce low friction, high pressure absorption capacity and an excellent wear protection. Even thin films produce an extremely stable layer in which the MoS2 fins slide to each other like a pack of cards.