Oils with high-performance additives for reliable lubrication

Oils dissipate heat well from the lubricating point. In addition, they have an notedly good creep and wetting behaviour. Therefore oil lubrication is often used at high temperatures or high speeds of rotation. Typical fields of application are gears, chains, friction bearings, hydraulics and compressors.

| Characteristic | Standard | Description |

|---|---|---|

| Viscosity | DIN 51561 | Dimension for the inner friction of liquids |

| ISO VG | DIN 51519 | Classification of oils into viscosity classes based on DIN 51 561 |

| Operating temperature | Temperature range of the optimal performance | |

| Flashing point | DIN ISO 2592 | Lowest temperature at which the vapour-air mixture catches fire through extraneous ignition |

| Setting point | DIN ISO 3016 | The lowest temperature at which the oil is still just capable of flowing |

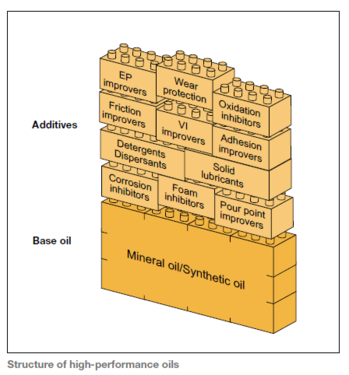

Structure of high-performance oils

Structure of high-performance oils

The additives play an important role in the formulation of a high-performance oil in addition to the careful selection of the base oil (type, viscosity) and has considerable influence on the price-performance ratio. Modern lubricating oils are conceived so that when the oil film is breached, the active ingredients form a protective film, so that the surfaces are protected against wear.

Properties of base oils

The base oil plays a decisive role in the selection of a lubricating oil. Mineral oils, synthetic hydrocarbons (polyalphaolefines = PAO), ester, polyglycols and silicone oils differ notably in their physical properties and chemical behaviour.

| Properties | Mineral oils | Synthetic hydrocarbons (PAO) | ester oils | Polyglycol oils | Silicone oils |

|---|---|---|---|---|---|

| Density 20 °C [g/ml] approx.: | 0,9 | 0,85 | 0,9 | 0,9 - 1,1 | 0,9 - 1,05 |

| Setting point [°C] approx.: | -40 -> -10 | -50 -> -30 | -70 -> -35 | -55 -> -20 | -80 -> -30 |

| Flashing point [°C] approx.: | < 250 | < 200 | 200 -> 270 | 150 -> 300 | 150 -> 350 |

| Resistance to oxidation | - | + | + | + | ++ |

| Thermal stability | - | + | + | + | ++ |

| Compatible with plastics | + | + | - | typenabhängig | + |

Compatibility of oils

The miscibility of different lubricating oils is influenced considerably by the base oils and has to be observed correspondingly when changing the lubricating oil, under consideration of the viscosity.

| Mineral oil | Polyalphaolefines | ester oils | Polyglycol oil | Silicone oil (methyl) |

Silicone oil (phenyl) |

Polyphenylether oil | Perfluorpolyethe oil | |

|---|---|---|---|---|---|---|---|---|

| Mineral oil | ■ | ■ | ■ | □ | ||||

| polyalphaolefines | ■ | ■ | ■ | |||||

| ester oils | ■ | ■ | ■ | ■ | ■ | ■ | ||

| Polyglycol oil | ■ | ■ | ||||||

| Silicone oil (methyl) | ■ | □ | ||||||

| Silicone oil (phenyl) | □ | ■ | □ | ■ | ■ | |||

| Polyphenylether oil | ■ | ■ | ■ | |||||

| perfluorpolyether oil | ■ |

■ miscible □ partially miscible

Viscosity – the dimension for the inner friction of liquids

The choice of the viscosity of an oil depends on the area in which the lubricant is used. The following basically applies: Low viscosity for low pressure stress and high sliding speeds, high viscosity for high pressure stress, low sliding speeds and high temperatures. The viscosity can be determined with different measuring processes (see Test and measuring processes). The kinematic viscosity in specified in mm2/s and is used for classification. The dynamic viscosity is specified in mPa s. The two viscosities can be converted into each other under consideration of the density with the equation:

Dynamic viscosity = Density x kinematic viscosity.

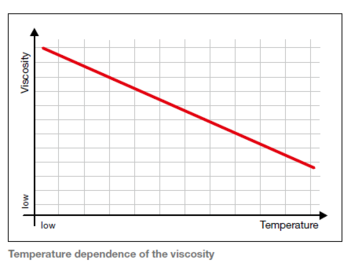

Dependency of the viscosity from the temperature

Dependency of the viscosity from the temperature

The viscosity of an oil depends on the temperature, the pressure and shear stress as well as the time in which it happens. The most important influencing factor is the temperature. As the temperature increases, the viscosity decreases and vice versa, depending on the type of oil.

The classification of lubricating oils into viscosity classes is effected to ISO (DIN 51 519) or SAE (Society of Automotive Engineers).

| Kinematic ISO-VG |

Viscosity (40 °C) [mm2/s] |

|---|---|

| 15 | 13,5 – 16,5 |

| 22 | 19,8 – 24,2 |

| 32 | 28,8 – 35,2 |

| 46 | 41,4 – 50,6 |

| 68 | 61,2 – 74,8 |

| 100 | 90 – 110 |

| 150 | 135 – 165 |

| 220 | 198 – 242 |

| 320 | 288 – 352 |

| 460 | 414 – 506 |

| 680 | 612 – 748 |

| 1.000 | 900 – 1.000 |

| 1.500 | 1.350 – 1.650 |

ISO viscosity classes to DIN 51 519

ISO-VG (Viscosity Grade) classes apply only for industrial lubricating oils. There are 18 kinematic VG classes from 2 mm2/s to 1,500 mm2/s. Determining of the viscosity is carried out at 40 °C.

Viscosity classes to SAE

Lubricating oils for vehicle gears and motors are classified into SAE viscosity classes. These range from 0 – 60 at motor oils and from 70 – 250 at gear oils. The viscosity values are measured at 100 °C.