Types of lubricants

Tribology is concerned wiht the scientific characterisation of friction, wear and lubrication and the development of technologies serving to optimise frictional processes.

A distinction is made between "tribomechanical" and "tribochemical" effects.

-

Read more

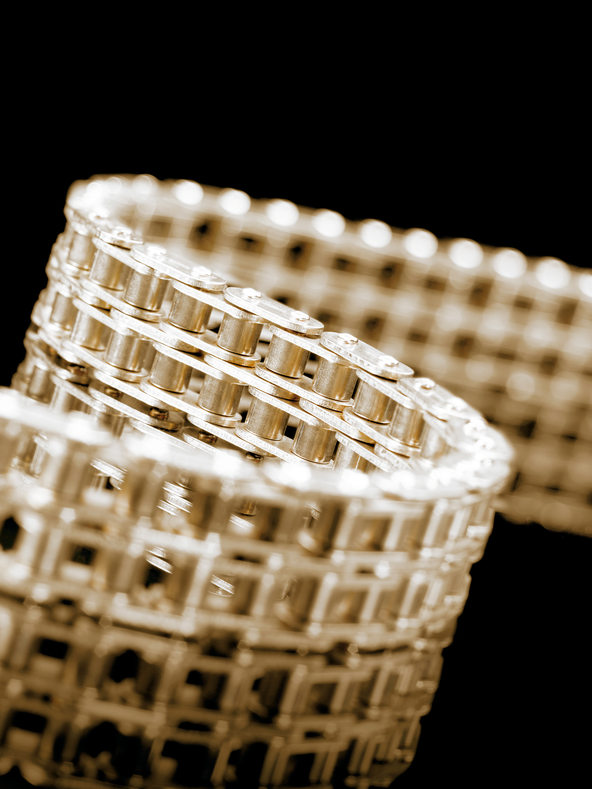

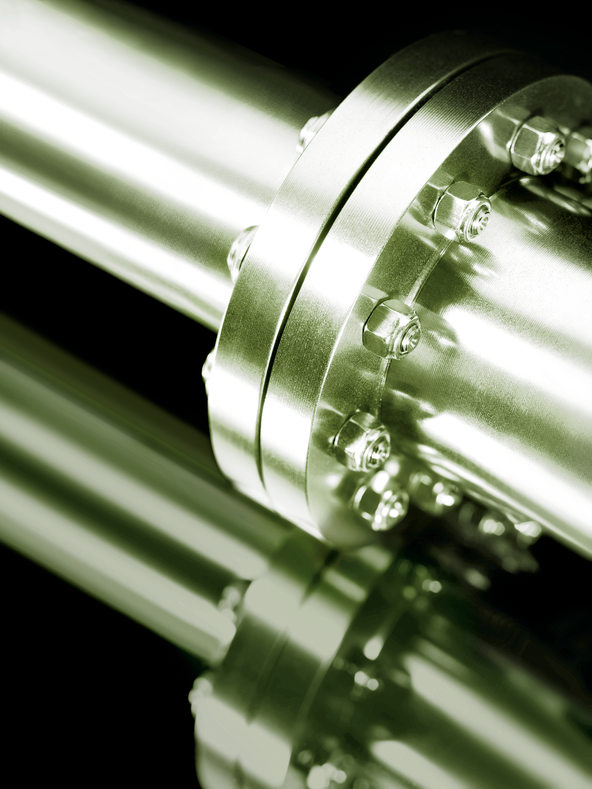

Oils dissipate heat well from the lubricating point. In addition, they have an notedly good creep and wetting behaviour. Therefore oil lubrication is often used at high temperatures or high speeds of rotation. Typical fields of application are gears, chains, friction bearings, hydraulics and compressors.

-

Read more

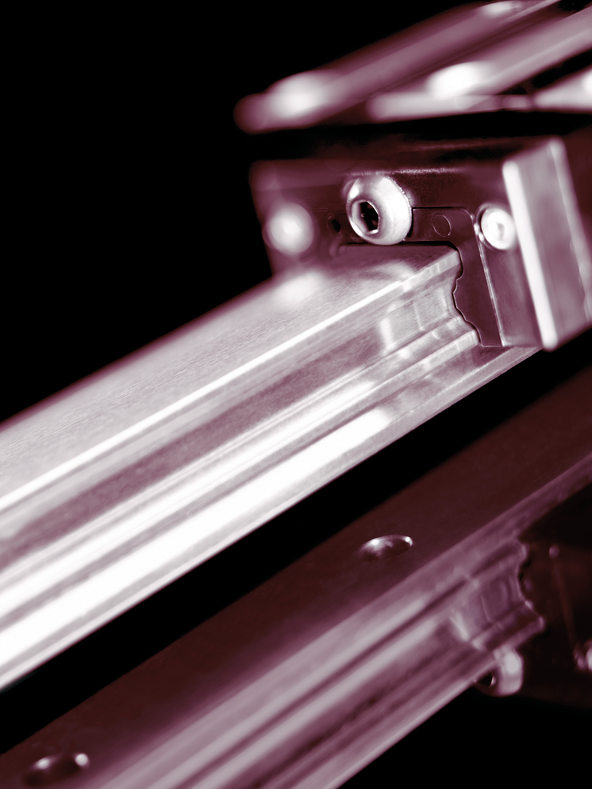

If, for structural reasons, no oil lubrication is possible or if a cooling function is not required, a lubricating grease is used in most cases. Greases consist of a base oil that is bound by a thickener (soap). This ensures that the lubricant remains at the lubricating point. There it ensures permanently effective protection against friction and wear and seals the lubricating point against external influences such as moisture and foreign matter. Greases are often used at rolling and friction bearings, spindles, fittings, seals, guides, but also at chains and gears.

-

Read more

The structure of pastes basically corresponds to that of greases. However, the share of solid lubricants is notably higher. This ensures reliable lubricating, separating and corrosion protection effects also when used under extreme temperature and pressure conditions and aggressive media. Pastes are used at screwed connections as well as when pressing in pins and bolts and furthermore at gearwheels.

-

Read more

Dry lubricants can be classified into powdery solid lubricants, ceraceous sliding films and solidcontent bonded coatings.

-

Read more

Corrosion Protection for reliable preservation during storage and shipping