OKS 432 High Melting-Point Grease

Lubrication of rolling bearings during paper manufacturing

OKS 432 is a special high-temperature grease on a mineral-oil basis with aluminium-complex soap as a thickener and additional EP additives. It is conceived for the lubrication of rolling and friction bearings under high loads and temperatures of up to 190 °C. The grease reduces wear on the bearings and thus protects them effectively against corrosion and against soiling from the outside.

Life without paper is simply unimaginable. Whether the morning paper enjoyed during breakfast or the magazine that we page through while waiting, whether the documents we copy or print at work, or whether writing cards or packing Christmas presents: We hold paper in our hand every day as a matter of course within wasting a thought on it. Thinking about it? About what? For example about where this plenitude of paper actually comes from. Or about how it is manufactured.

Paper is based on cellulose or fibrous materials that are manufactured from wood that is treated mechanically or chemical-mechanically. In early days paper had to be tediously scooped from a pulp, pressed and dried by hand. Making it unaffordable for the common people - and reserved for the scriptoria in the cloisters, the bureaus and administrative offices as well as trading companies to draw up records and keep book.

Nowadays paper is produced on a large industrial scale on machines. To this purpose the raw materials are immersed in water and broken down into individual fibres. In order to obtain the desired paper quality, these paper fibres are treated correspondingly before being passed on to the paper machines. The paper fibres are passed through the individual manufacturing steps of headbox, screen/formers, pressing, pre-drying, size press and post-drying onto the paper machine to form a continuous paper web which, at the end of the manufacturing process, is wound onto reels weighing up to 100 t each.

The actual paper manufacturing process takes place in the screener and former sections, where the paper fibres are placed on a screen and the water extracted in order to obtain an increasingly compact fibre web having a dry-matter content of approximately 20 %. This web is passed on to the press section, consisting of several roller units, for further removal of water, thus increasing the dry-matter content to about 45 %. In the subsequent dryer section the paper web is guided around a large number of steam-heated hollow cylinders, thus heating the paper web further and through evaporation of the residual water drying the paper to a dry-matter content of approximately 94 %.

Specific paper properties, such as their suitability for printing or writing and colour, are influenced correspondingly in the size press by applying chemical aids and pigments to the paper web surface.

Example of use

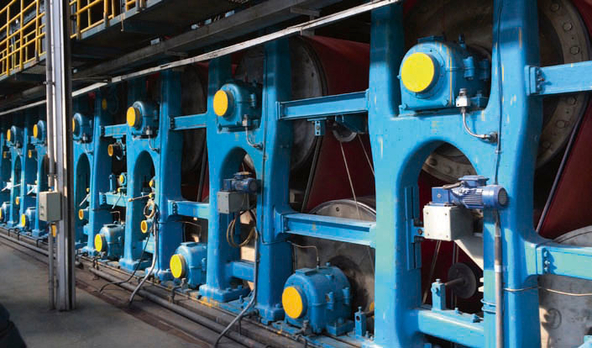

A large paper manufacturer in China uses the High Melting-Point Grease OKS 432 to lubricate the rolling and friction bearings of the various transport units which convey the paper webs through the paper machines with a length of up to 100 m.

The high tensile loads from the paper webs reigning within the paper machines cause an extremely high load on these bearings during operation. In addition, the paper manufacturing process itself means that the bearings are not only subjected to high ambient temperature, but also to major water and vapour influence Even under these operating conditions the High Melting-Point Grease OKS 432 ensures reliable functioning of the bearings. This fact not only results in less downtimes, thus notably increasing the service life of the paper machines, but provenly also reduces the high maintenance and repair costs for these complex machines.

The overall requirement for OKS 432 lies at approximately 600 kg per year at this production site.

Advantages and benefits

- Temperature application range up to 190 °C

- Good pressure resistance

- Excellent wear and corrosion protection

- Good resistance to oxidation and ageing