Intelligent additive technology with Mox-Active: Reducing cost and environmental impact

The task of the additives is to optimise lubricants for the respective application with regard to corrosion and wear protection, emergency running properties, oxidation stability, temperature characteristics and wetting behaviour. The careful selection and the intelligent combination of the additives guarantee the high performance of OKS speciality lubricants.

Mox-Active additive

OKS speciality lubricants with the Mox-Active additive technology developed by OKS contain molybdenum complex compounds for increased performance.

Effect on the surface

Lubricants with Mox-Active are responsible for the smoothing of the metal surfaces at the lubricating points. Intelligent additives support and accelerate the flow smoothing process on the otherwise rough surfaces and effect a tribological surface coating. The run-in times can be shortened considerably.

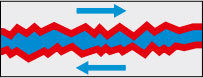

Phase 1

Mox-Active is deposited under pressure at the stressed metal surface of the lubricating point.

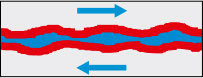

Phase 2

As the stress increases, a pressure-stable and effective lubricating protective layer is formed and increases the pressure absorption capacity. Friction and wear are reduced considerably.

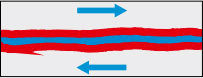

Phase 3

Mox-Active supports and accelerates the flow smoothing process of the metal surface. Best results are achieved here in combination with MoS2. This structural change produces a tribological surface coating with extremely low coefficient of friction and high wear protection.

Cost reduction and reduction of environmental impact

OKS speciality lubricants with Mox-Active reduce the operating costs, increase the quality in production and reduce the environmental impact through lower lubricant consumption and lower energy requirements.