Sustainability at OKS

OKS takes responsibility for people and the environment. The basic and raw materials for OKS products come from all over the world and OKS delivers their products all over the world. Therefore the company takes responsibility not only for the immediate environment of the German headquarters. When designing processes sustainably and when developing new products, safety is of crucial importance for OKS. Safety always refers to the protection of people, whether they work for OKS or with OKS products. Safety also refers to possible effects on the environment that result from producing or applying the products.

OKS – a part of the bigger picture

Sustainability is an important component of the Freudenberg corporate culture

The concept developed by OKS is based on the strategy of the Freudenberg Group as the parent company of OKS. It defines sustainable action as part of the corporate culture with its values and principles. The relevant economic and social environment including the value creation chain rounds off the key areas. The values and principles of Freudenberg form the focal points: Value for the customer, innovation, management, people, long-term orientation and as the central statement in achieving more sustainable action: Responsibility

Sustainability at Freudenberg

OKS is aware of its responsibilities

In its concept for sustainability OKS considers the complete value chain and continuously asks:

- How can the company design business processes efficiently, sustainably and responsibly and spare resources?

- Which products and solutions can OKS develop so that customers and users manufacture more efficiently and sustainably or their end products use fewer resources?

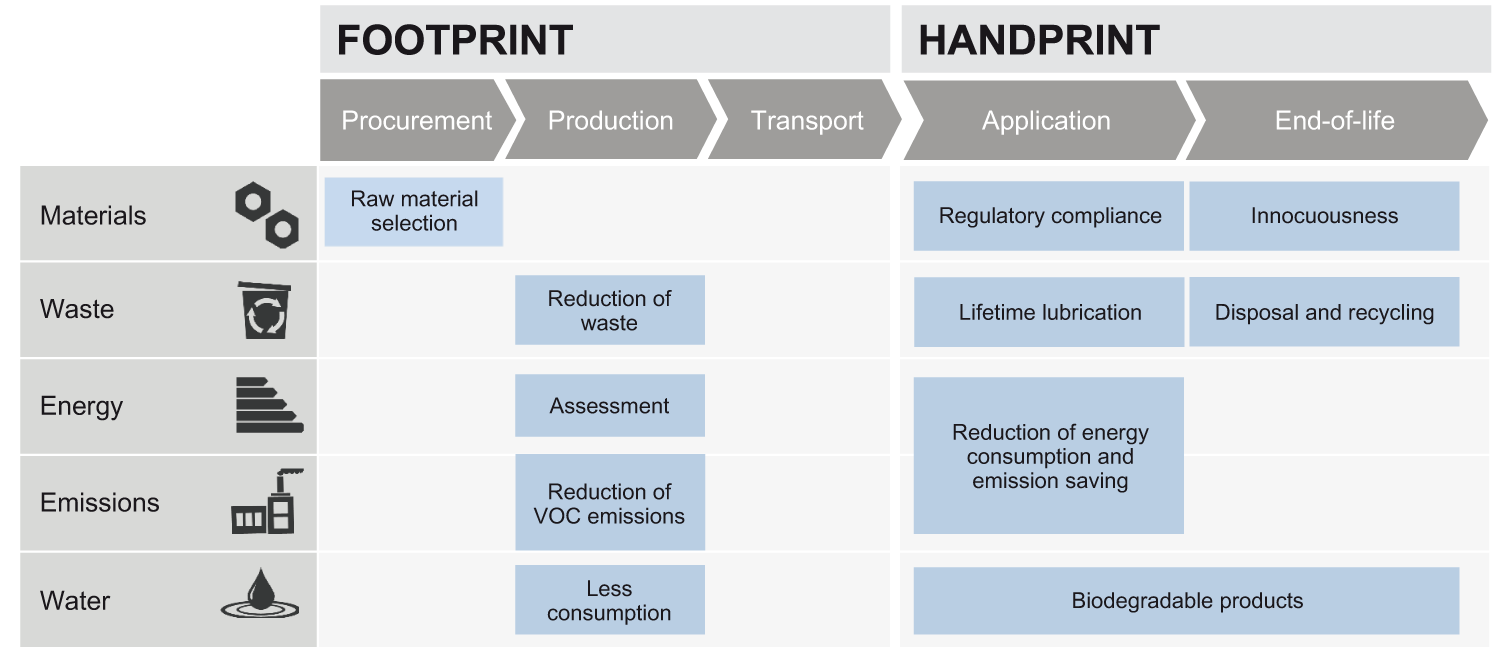

Image: OKS sustainability matrix

Image: OKS sustainability matrix

Minimizing our footprint: OKS spares resources

OKS pursues the goal of minimizing possible negative effects of its corporate activities and thoroughly questions direct influences of its business activities on the environment and society. To minimize its own footprint and sustainably manage the value chain, OKS is implementing comprehensive programs with in part significant investments with the goals: Reduced energy consumption and as a result reduced CO2 emissions, reduced emissions through closed manufacturing processes, recycling of specific operating materials such as solvents, reduced waste in the production process (packaging and production materials), efficient insulation of company buildings and as far as possible local purchasing of raw materials to shorten transport routes.

Increasing the handprint: OKS combines customer benefit and sustainability

Economic and social actions are compatible. OKS develops and produces at a central location in Germany and reacts in a timely manner to current environmental requirements and new demands from customers. Innovative technologies can be developed rapidly in the in-house laboratory and implemented into marketable and sustainable products for OKS customers and users. With specific targeted measures OKS supports you in making your operations more sustainable, producing more efficiently and reducing negative impacts on the environment.

In the process OKS focuses on the customer benefit and deliberately takes on responsibility in the spirit of sustainable action.

Some examples of this:

Products: Comply with food safety and do not present any health risks

OKS develops special lubricants for the nutrition and food industry. In this industry, products are subject to high requirements and strict legal provisions. Companies such as producers of food and beverages or operators of logistics centres for food face a challenge in the product selection. Because no one wants lubricants in their food. Food is mostly produced industrially and mechanically. Where machines are running, components are moving. These have to be lubricated reliably and at the same time a high standard of safety for the food has to be ensured.

OKS meets this responsibility: The developed lubricants are nationally and internationally recognised and approved for the food industry. They comply with all legal provisions. Customers and users of OKS obtain products that are not harmful to health and highly efficient.

Image: Lubricant for the food processing technology with NSF H1 approval

Further information: Speciality lubricants for food processing technology

Avoiding waste: Lifetime lubrication

Modern lubricants have a significantly longer service life than conventional lubricants. A longer service life means less machine downtimes and reduced maintenance costs for machines and plants. OKS uses this knowledge to the benefit of its customers and users. In the in-house laboratory, experts develop lubricants that ensure extended maintenance intervals for machines and plants. This reduces the use of resources and the downtimes.

For a lifetime lubrication a component such as the rolling bearings of a machine only have to be lubricated once during the complete life. Efficiency that is almost unbeatable and re-lubrication furthermore becomes superfluous.

OKS customers and users benefit twofold: Less friction at important components increases the service life of the entire plant. When using OKS lubricants, customers and users use fewer lubricants. Therefore notably lower quantities of used lubricants accrue that have to be disposed of in the end.

Image: Lifetime lubrication

Reducing the amount of waste: Refillable spray cans

A spray can has a short service life and ends up as refuse after its use. OKS advocates waste reduction and invests in alternative solutions to reduce the number of spray cans used only once by customers and users. The experts have developed a secure and economical Airspray system that consists of a refillable spray can and a filling station. The can can be refilled via the system with a number of different OKS products. Customers and users benefit noticeably from the reduction of waste and receive a system that works with pure compression force as the propellant.

Image: OKS Airspray can

Increasing efficiency: Precision maintenance cycles of machines

When numerous machines and plants are used, industry businesses and business enterprises have to periodically supply the friction points with new lubricants. For this requirements OKS offers a special ChronoLube system. Electromechanical lubricators can be equipped with different OKS greases and oils in this system. On the customer and user side, the system provides for requirement-based and pinpoint lubrication of the individual components. Under- or overdosing is not possible. Resources can be spared and the media can be used sparingly and efficiently.

Image: OKS ChronoLube system

Saving energy and reducing CO2 emissions

Low wear of machines and plants means less energy consumption for customers and users. The wear of plants and machines can be reduced with highly efficient lubricants. They run reliably and without malfunctions. OKS develops special lubricants for this that reduce coefficients of friction at the decisive positions. Customers and users profit from lower energy consumption of the plant. Depending on the energy type used, the related CO2 emissions can be reduced on the customer and user side. Short procurement and transport routes also reduce emissions. OKS procures the required materials mostly regionally and produces its products locally at the domestic location in Maisach (near Munich).

Image: Automatic chain lubrication with OKS 3751; reduced lubricant consumption, longer durability of the chain

Protecting water and the environment: Biodegradable products

Operators of the wind turbines are obliged to remove any residues at regular intervals from all rotors. Deposits may negatively influence the aerodynamic behaviour of the entire plant as well as the energy yield. When cleaning on location, media may be released to the environment. Therefore an environmentally compatible usage of these cleaning agents on offshore facilities on the high seas is indispensable. It is imperative to protect the delicate ecological balance of the oceans in the long-term.

OKS is aware of this responsibility and develops special cleaning agents for the manufacturers and operators of wind farms that are biodegradable and clean the rotors effectively. Similarly high requirements exist when building passenger and container ships in the shipyards, in marine technology and for operators of offshore facilities in the oceans. For these and other fields, OKS develops special easily biodegradable high performance gear oils and supports their customers and users in sustainably protecting water and the environment.

Image: Cleaning of rotor blades of a wind turbine

Further information: Special lubricants for shipbuilding and marine technology

Environmental agreement for Bavaria:

OKS is a member of the "Umweltpakt Bayern" (Environmental agreement for Bavaria), an initiative of the Bavarian state Ministry of the Environment, Health and Consumer Protection for practised environmental responsibility in companies.

OKS is a member of the "Umweltpakt Bayern" (Environmental agreement for Bavaria), an initiative of the Bavarian state Ministry of the Environment, Health and Consumer Protection for practised environmental responsibility in companies.

The detailed OKS Sustainability Report 2018 you can

read online here