Advantages for the rubber and plastics industry

- Specially developed for flexible use throughout the entire production process

- High resistance under pressure and at extreme temperatures

- No lubricant residues in machines and components

- Longer machine service life cycles thanks to low wear

- Fewer maintenance and cleaning requirements

Flexible solutions for the rubber and plastics industry

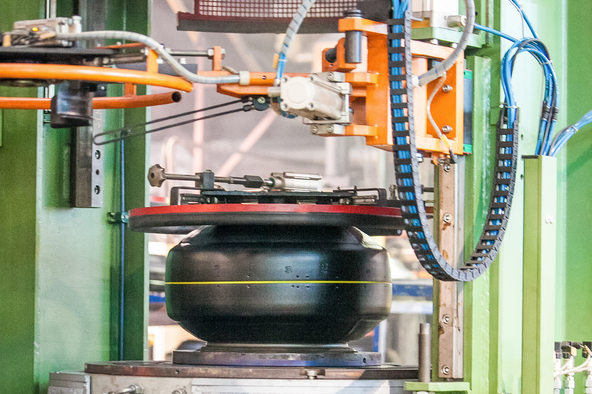

Requirements for lubricants are highly varied in rubber and plastics production. Widely different processes require flexible solutions with excellent characteristics, whether for injection molding, extrusion processes or film and tire manufacture. Plastics manufacturing and processing demand lubricants which allow production lines to work dependably over many cycles. It is essential to supply typical friction points with sufficient optimum lubricant on a permanent basis, even under high pressure and at extreme temperatures. The greases used must not leave behind any residues in machines and components. OKS has developed precisely the right lubricants for such needs. These highly effective solutions ensure low maintenance and cleaning requirements, thus boosting productivity.

Lubricants which withstand all mechanical loads

Production lines and components are subject to heavy wear when there is no optimal lubricant protection from special solutions such as extreme-temperature bearing grease. OKS solutions offer excellent compatibility with plastics and elastomers and impress with their long-term rolling and friction bearing lubrication thanks to high heat resistance. Special greases are applied to provide optimal lubrication for ejector pins in the plastics industry. These greases increase pin service life and protect against premature wear, thus minimizing maintenance costs and downtimes. Fast-running chains and other heavily used machine elements require dependably resilient chain and adhesive lubricants. For example, lubricants need to be capable of withstanding high pressure at high temperatures between the rail and sliding block in stretch wrapping machine chain systems. OKS lubricants are particularly suitable for lubricating flexible drives since they remain strongly adhesive and highly capable of creep, even under extreme conditions.

Painstaking research work and many years' experience in the sector go into the development of highly effective OKS lubricant solutions. Greases, oils, and pastes are thus produced for the rubber and plastics industry which reliably protect components, ensure a long service life and minimize maintenance costs.